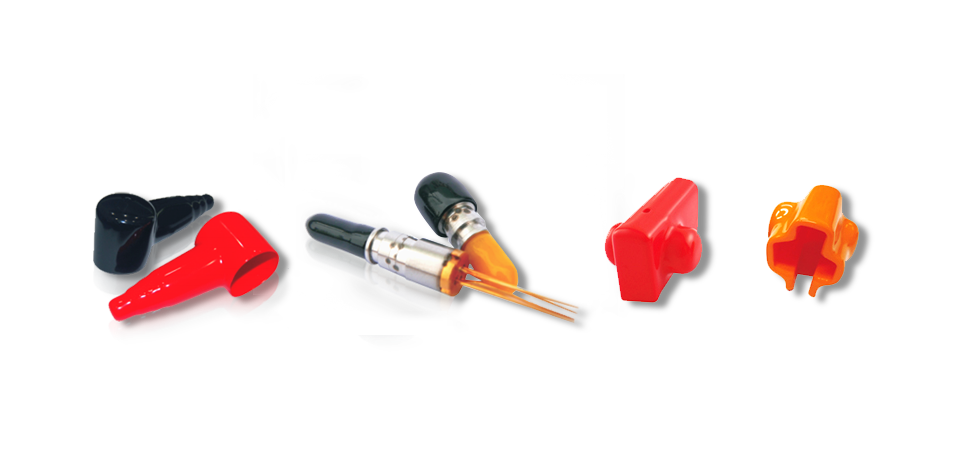

Many protective plastic products can be processed by plastic dipping equipment and injection molding equipment at the same time. The two processing methods have their own advantages and disadvantages, and it is difficult for the manufacturer to decide which processing method to use. However, compared with injection molding equipment, dip molding equipment has many advantages. Generally speaking, there are several reasons for replacing injection molding equipment with plastic dipping equipment

1. Cost: Generally speaking, the cost of dip molding is very low compared with that of injection molding. This is mainly due to the low cost of plastic processing equipment itself, mold processing costs and materials used for plastic processing.

2. Shorter mold product design cycle: mold manufacturing in plastic dipping processing equipment is a simple process (reverse design processing according to product structure). The process of dipping is to immerse the mould into the dipping liquid and then harden it. The injection mold design and production cycle is long and complex.

3. Rapid design of the structure of various products: for dip processing, it is very convenient to change the raw materials or design the structure of products in the product line. By immersing the same mold in different dipping solution, the material products with different strength and structure can be prepared quickly to meet the application in different fields.

4. Simple, one-step molding: the dip molding process is very simple. All the plastic dipping equipment only immerses the mold into the plastic dipping liquid. Once the plastic dipping liquid hardens, the product can be formed. There is no auxiliary demoulding, molding and melting device in the production process.

5. There is no fusion line for the product: the injection mold usually has fusion line at the parting surface of the mold. This fusion line will make the strength of the product joint worse. However, the product will not produce fusion line, and can bear the external force uniformly from all angles of the product, without any weak strength concentration point.