1、 Medical order completion

"Good products are not checked out, but are made in a down-to-earth way like your company." When the customer came to our company to inspect the goods, he said with admiration. 2.5 million endotracheal intubation indicating airbags were produced in more than one month with the cooperation of various departments. After quality inspection by customers, the qualified rate reached 99.96%

Before that, customers have been using blow molded indicator air bags. After contacting our dipped air bag products, they learned that the integrated molding of dipped air bags can effectively avoid the risk of air bag rupture during use. Although the price of Fangpu's dipped plastic air bag is higher than that of blow molded air bag, considering that the product quality can be improved, the customer resolutely chose Fangpu's dipped plastic air bag.

Due to the change of materials, customers strictly put forward a variety of test requirements to us, such as the consistency of airbag size, raw material migration test and so on. We don't dare to be slighted or despised, because we know that the high requirements of customers are the direction and driving force for Fangpu's progress, and this is also the most basic quality attitude in the medical industry.

Subsequently, our technical team carried out the test one by one according to the customer's requirements, and all of them passed the customer's verification. Fangpu people are dedicated and tenacious, and the spirit of doing small things has been recognized by customers. In the end, customers chose us and sent us the whole batch of orders. We have also become the only supplier of the accessories.

After the customer's formal order, the company immediately organized a group meeting to evaluate the stability of process and equipment. The production department calculates the production capacity, allocates the personnel, controls the delivery time, and the quality department also follows up the whole process to make the preparation for the production.

At the end of September, 2.5 million air bags were officially put into production. The key lies in the quality control of the production process, for which we carry out internal daily sampling inspection and send samples to customers weekly to confirm the product quality.

At the beginning of production, the quality control personnel found that the packaged products had serious extrusion deformation. In order to overcome this problem, the relevant personnel adjusted and modified the packaging scheme for many times, which greatly improved the problem of product deformation. Technicians have done a lot of verification experiments on the stress relief of products after deformation, and provided customers with solutions to the problem of product failure caused by deformation.

At the beginning of November, the customer flew from afar to Fangpu company to inspect the goods. The customer sampling inspection is very strict, taking photos in the whole process, taking 1-2 bags of products from each box for inspection, and the whole process is meticulous. In the final 2500 samples, only one bubble was unqualified because of its thick thickness, and all the others were qualified, with a qualified rate of 99.96%. Customers also randomly check whether the boxes are clean and whether there is ash in the goods stacking area. The result is that the boxes are clean and dust-free, and the products are clean and dust-free. This is a great affirmation of our production environment and packaging process.

So far, the order has been successfully delivered. Thank you for your hard work! In the face of customers, our service is supreme, and we are meticulous in our work. Through the cooperation of the team, to achieve high standards, high quality, efficient development.

2、 Popular science of medical devices: endotracheal intubation and its accessories

Novel coronavirus pneumonia has swept the world, and demand for detection reagents, respirators and respirators has risen sharply worldwide, which has greatly promoted the global development of China's medical device enterprises. As one of the most important segments in the whole medical and health field, the scale of China's medical device market has been more than one trillion of terminal procurement scale, showing a steady growth trend.

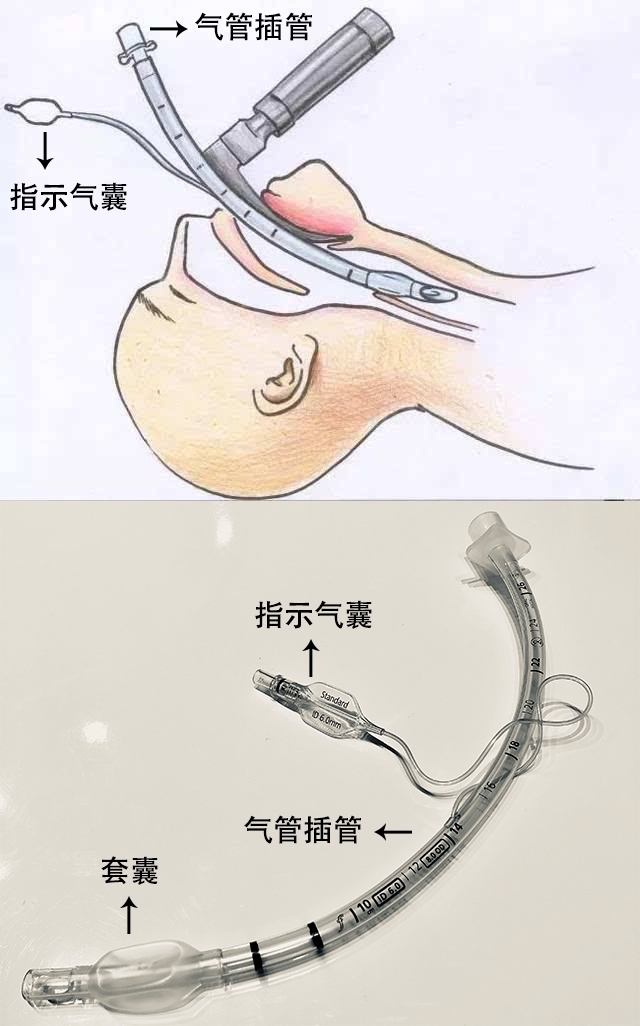

Endotracheal intubation (also known as endotracheal tube) is a kind of medical device that is inserted into the trachea and / or bronchus of patients to create a temporary artificial respiration channel for patients, especially those who cannot breathe autonomously. The common intubation head has one or two cuff. After inflation, the cuff can fix the intubation and seal the airway. The intubation tube body is usually made of high molecular material, and the steel wire coil is embedded in the tube body to improve the radial strength and axial flexibility. Part of the intubation tube is made of anti laser material or lamination to resist laser irradiation. Intubation for nasal / oral or percutaneous insertion of the patient's trachea. One end is connected with the anesthesia ventilator through the breathing pipeline to maintain the patient's breathing. Sterile, disposable. Indications: general anesthesia, cardiopulmonary resuscitation, mechanical ventilation, neonatal asphyxia, tracheal collapse, etc.

The distal part of the catheter was inclined to open.

The distal part is provided with sleeve like inflatable sleeve.

The near end is provided with a connecting pipe connected with the respirator.

The cuff is connected with the test balloon by a fine catheter to understand the expansion and contraction of the cuff and its inflation pressure.

Murphy side hole is located on the side wall far away from the distal sleeve of the trachea tube. Its purpose is that when the inclined port of the tracheal tube is attached to the tracheal wall, the breathing gas can be changed into and out through this side hole.

If the cuff inflates too much and oppresses the tracheal mucosa for a long time, the blood circulation will be affected, resulting in ischemic injury or even necrosis of the tracheal mucosa, followed by scar formation leading to tracheal stenosis and perforation in severe cases; When insufflation, it will lead to airway leakage, resulting in tidal volume loss, aspiration and other complications. Therefore, it is very important to indicate the airbag here. The indication balloon will be filled together with the cuff, and the filling state will be clearly indicated, so as to avoid the situation of over inflation and under inflation.

The indicator air bag produced by Fangpu adopts the integrated molding of plastic dipping process, which has the advantages of simple structure, safe material, good air tightness, high pressure resistance and leakage detection. It is also suitable for double lumen bronchial intubation, tracheotomy intubation, PVC laryngeal mask, tourniquet, urinary catheter and other medical devices that need to indicate the gas filling state.

In today's epidemic situation, Fangpu company focuses on the impregnation molding process and provides solutions for the impregnation molding of medical devices. We use social resources to provide better protection for doctors and patients.