1、 Introduction

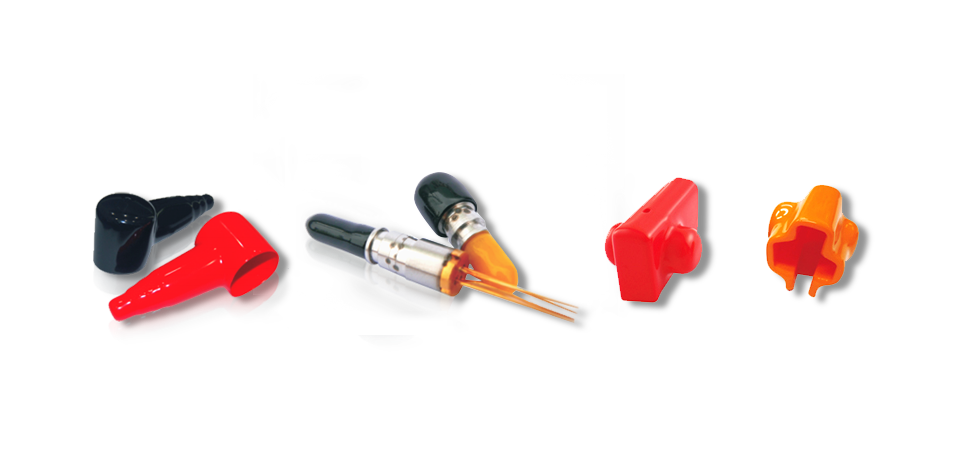

According to the latest global product structure of electronic components, connectors have become the second largest pillar industry of electronic components after PCB, and the demand and technical requirements of various industries for connectors are constantly improving, which leads to more investment in R & D and production for connector parts manufacturers. It includes the protective cap, as one of the components of the connector, which has the functions of insulation, shielding, dust-proof, oil proof and moisture-proof. Dip molding is one of the more mature technologies for manufacturing protective caps, such as insulating protective sleeve of quick connect terminal (abbreviated as terminal sheath), protective cap of RF coaxial connector, protective cap of high-speed connector, etc., as shown in Figure 1.

Figure 1 quick connect terminal sheath (a), RF coaxial connector protective cap (b), high speed connector protective cap (c)

In the face of the diversification trend of connector structure and model, the advantages of liquid impregnation technology in the manufacture of connector protective cap are gradually reflected; This paper will introduce the process of liquid impregnation and its advantages and disadvantages.

2、Introduction of liquid impregnation process

The coating of liquid impregnation is thick and soft, which can be separated from the mold as a protective product.

1、The role of liquid immersion protective cap in the field of connector

The main functions of the plastic immersion protective cap in the field of connectors are as follows:

(1) Provide flexible protection during transportation, handling and storage to avoid scratch and deformation.

(2) The surface of the protective cap is free of oil and dust, and has certain antistatic effect (surface resistivity ≤ 1011 Ω · cm), and has good effect of preventing dust and water.

(3) The raw materials used for the plastic immersion protection products are PVC paste resin and silica gel materials. Silica gel has higher performance, and the high temperature resistance is greater than 150 ℃, and the low temperature performance reaches -60 ℃.

(4) Environmental protection, no secondary pollution, the protective cap will not release volatile substances during the use process, especially plastic impregnated silica gel products. It is an odorless, odorless and halogen-free environmental protection material, which can meet the high requirements in military, aviation, optical fiber connectors and other fields.

(5) Flame retardant: the grade of hot wire (GWIT) of PVC impregnated plastic products reaches 800 ℃ /mm, while that of silica gel impregnated products reaches 900 ℃ /mm.

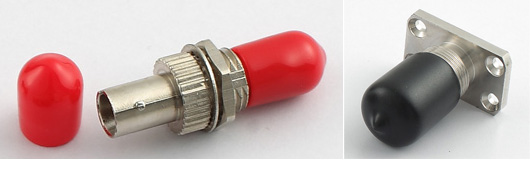

(plastic impregnated silicone protective cap)

2、 Liquid impregnation process

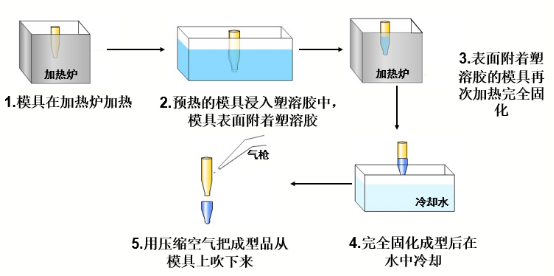

The liquid impregnation process mainly includes preheating, impregnation, plasticization, cooling and demoulding.

(1) Preheating: the mould is sent into the oven and heated evenly;

(2) Dipping: immerse the heated mold into the plastisol and control the lifting speed of the mold;

(3) Plasticizing: reheat the dipped mold to plasticize the plastic sol.

(4) Cooling: reduce the temperature to normal temperature after plasticizing.

(5) Demoulding: use compressed air to separate the molding products attached to the mold.

As shown in the figure:

3、 Development of liquid impregnation equipment

Liquid immersion equipment mainly includes oven, immersion tank, cooling device, demoulding device, electrical control system, immersion mold and mold conveying system.

射频同轴连接器防护帽模具

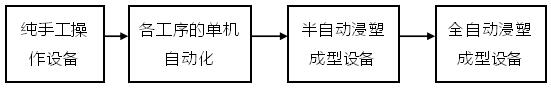

Development history of liquid impregnation equipment:

Fangpu's liquid impregnation equipment has experienced about 15 years from pure manual operation to fully automatic operation. At present, the automatic liquid impregnation equipment (see Figure 5) has realized the continuity of each process. Its advantages are as follows:

1. The production efficiency is high. Take the terminal sheath as an example, the daily output can reach 300000 pieces / set;

2. The cost of manpower is low, from one person managing one machine to one person managing multiple machines;

3. Also makes the quality of the product has been well controlled.

In the future, the liquid impregnation equipment will develop in the direction of refinement and intelligence, which is also the future development direction of Fangpu equipment.

3、Advantages and disadvantages of liquid impregnation process

Many connector protective caps can adopt liquid impregnation process because of its own process characteristics

Advantages:

(1) The development of new products is fast, generally it takes only 2-3 days from mold opening to sample coming out, which is in line with the trend of rapid connector development;

(2) The mold cost is low, only the male mold, the cost ranges from hundreds to thousands, the structure design is flexible;

(3) High batch efficiency reduces the inventory cycle of customers;

(4) The strength of the product is uniform, and there is no stress concentration point in the product;

(5) Low energy consumption (hydropower).

inferiority:

(1) The thickness uniformity is not easy to control, the process itself is limited, and the product thickness tolerance is slightly large;

(2) Only male mold, can't process the product with too complex structure (such as snap sleeve).

4、Conclusion:

This paper describes the characteristics of liquid impregnation process in detail, and introduces that liquid impregnation protective cap has the advantages of short product design and manufacturing cycle, simple manufacturing process, low material cost and operation cost, which is a technology worthy of promotion in this field. With the continuous improvement of polymer material technology and impregnation equipment technology, liquid impregnation technology will provide more and better products for reliable connection of connecting devices.

(the original text was published in the second issue of electromechanical components, 2015)